Description

Some of the tools I most enjoy using are either made in small numbers by artisan craftsmen or by me in my workshop in Newhaven, East Sussex. In fact a few of those tools have been used to make your gauge, so thank you for taking a look and considering adding to that tradition.

Design

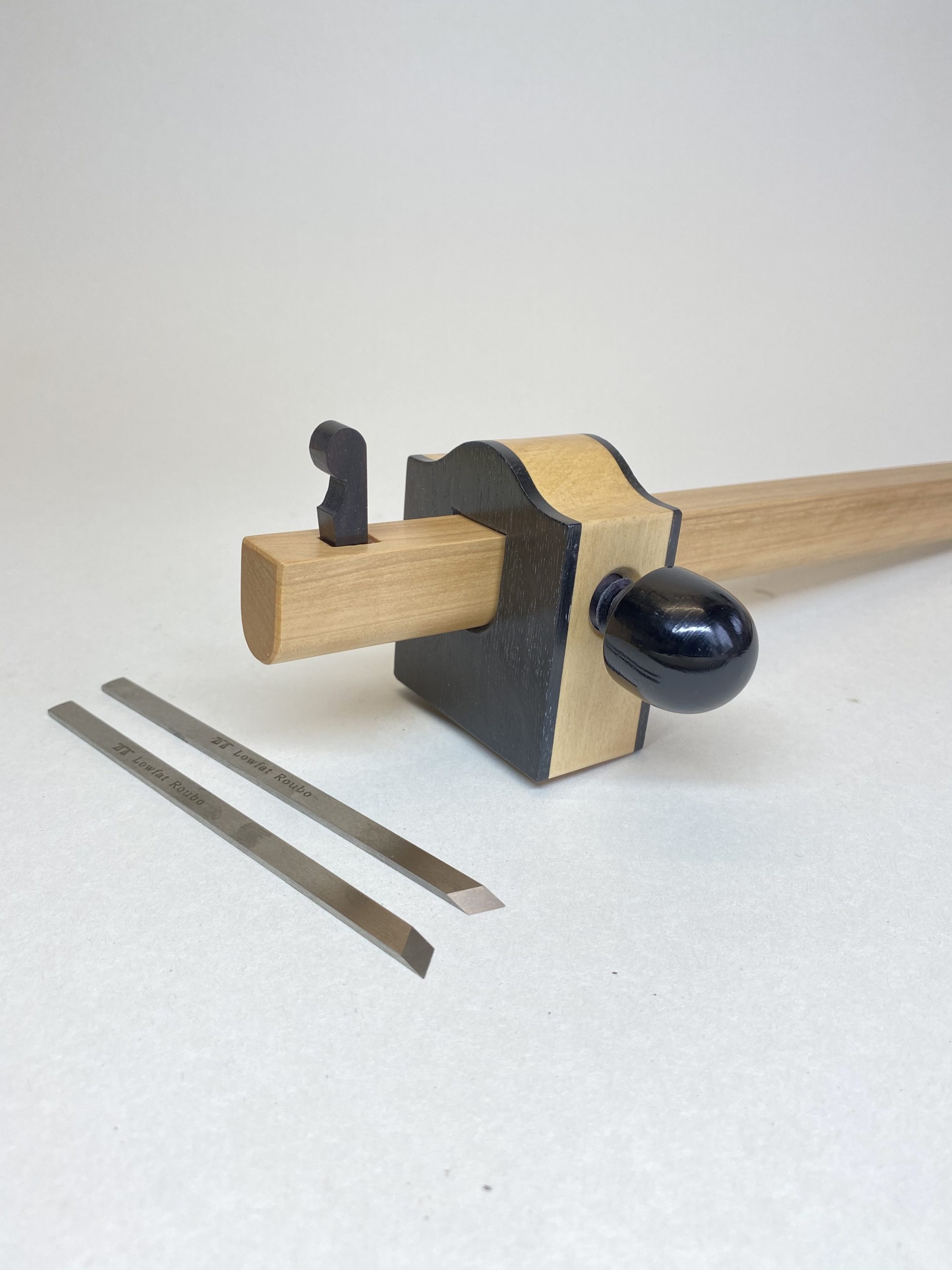

The design brief for this tool and other Lowfat Roubo products is one of simplicity and economy in either materials or components, or sometimes both. I have a number of gauges in my everyday tool kit; some fancy and extremely accurate for generating baselines for dovetailing or shoulder lines for joinery and some for less critical early stage marking out. This gauge is one of the former. The beam is married to the stock early on in the making and is made to be a loose friction fit whichever way round it is used. Most adjustments can be made while holding the beam in one hand and advancing the stock with a flick or push of the thumb in one direction or by allowing gravity to work for you in the other. The screw fastener has a leather pad on the end to resist marking the beam when tightened and to achieve a firm and reliable setting. I recommend you make sure the screw is fully retracted into the stock when swapping the beam round.

Blade options

These gauges come with two high carbon steel blades ground with a skew angle of 30° left and right. The bevel is 20°. These angles have been chosen to enable you to re-grind and hone using a Lie Nielsen honing guide fitted with their 30° skew jaws. For more information about this setup take a look at my blog at lowfatroubo.co.uk. The blade can be switched to have the flat ground edge facing either way in the beam to ensure you get the most accurate gauge line. It is also sufficiently robust to cut veneers and even sections for inlay. This gauge works best when pushed or pulled in one direction depending on which way round you have the blade set in the beam. A two blade set covers all eventualities for both left and right hand users.

Additional blades and wedges

Extra blades can be ordered here as well as a spear point blade and spare wedges.

Finish

These gauges are finished with a thin coat of very dilute blond dewaxed shellac before cutting back to a semi matt finish with a ‘shop made hard paste wax. The screw thread is made from Lemonwood, also known as Castelo boxwood. It is an excellent alternative to European box and responds well to ebonising. In time you may notice the natural colour of the wood appear on the surface.

Reviews

There are no reviews yet.